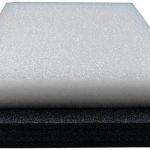

Closed cell foams are closed cell, chemically cross linked (and non cross linked) foams made from polyethylene or ethyl vinyl acetate copolymers. They are made using an extruded or block form method. They are made in a range of densities and molecular weights.

Polyethylene and EVA foams are buoyant, waterproof, lightweight, shock absorbing and have excellent thermal insulation properties. They are used in a wide range of applications including expansion joints, packaging, impact absorption, thermal insulation and backing rod. They are resistant to most common chemicals and have good compression characteristics.

The advantages of this particular foam versus open cell foam include its strength, higher R-value, and greater resistance to the air leakage or water vapour. To calculate the R value of EVA or PE, just divide the thickness by the thermal conductivity value. The value for this product is .033 degrees per w.m.k. (i.e. 50 mm = 50 divide by 33 = 1.515 R value).

Features

- Impact and vibration absorption properties

- Can operate at medium-high service temperatures

- Weather and chemical resistant, including splash resistance to fuels and oils

- Excellent buoyancy with low water absorption

- Thermal and acoustic insulation characteristics

- Suitable for thermo-moulding and thermo-forming

- Low thermal conductivity value

- Provides no food for pests

- Resistant to rot

- Flame retardant additive

Applications

Generally speaking, closed cell foam consists of trapped gas bubbles formed during the foam’s expansion and cure. The trapped gas bubbles increase the insulation properties of the cured foam. The cured foam must be strong and of a medium density in order to lock in the gas bubbles. The foam’s strength, together with its closed cell nature, enable it to resist liquid and function as a vapour retarder. As such closed cell foam has many applications such as flexible thermal insulation, protective impact barriers, packaging and marine buoyancy. It is also suitable for creating fiberglass moulds and for use in applications where polystyrene is not strong enough.

Contact Future Foams today for a free no obligation quote!