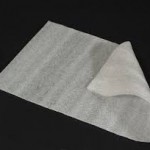

Expanded Polyethylene (EPE) is a closed cell non-cross linked PE Foam product which is a produced using low density Polyethylene resins with HCFC & CFC free gasses. Along with being a lightweight material, EPE Foam is also non-abrasive and chemically inert, water resistant and environmentally 100% recyclable.

EPE is used in many applications as it displays characteristics which are suitable for lots of different industries. It has relatively high thermal properties so its used as a flexible thermal barrier. It has a soft texture making it the ideal packaging solution for highly polished surfaces, non-static for electronic goods as well as providing cushioning against shock for fragile items.

EPE comes in a variety of thickness giving customers a greater choice for their requirements.

| Thickness | Width | Length | Thickness | Width | Length |

| 1 mm | 1200 mm | 100 Meters | 8 mm | 1200 mm | 50 Meters |

| 1 mm | 1200 mm | 500 Meters | 10 mm | 1200 mm | 45 Meters |

| 2 mm | 1200 mm | 100 Meters | 20 mm | 1000 mm | 2000 mm |

| 3 mm | 1200 mm | 100 Meters | 30 mm | 1000 mm | 2000 mm |

| 4 mm | 1200 mm | 100 Meters | 40 mm | 1000 mm | 2000 mm |

| 6 mm | 1200 mm | 70 Meters | 50 mm | 1000 mm | 2000 mm |