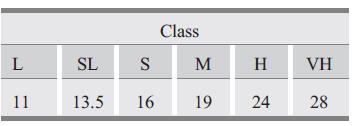

Expanded polystyrene foam (or EPS) is a closed cell, resilient, lightweight rigid cellular plastics material produced in a range of densities between 13.5 kg/m3 and 28 kg/m3. The grades of expanded polystyrene we keep in stock are SL, M, H and VH grade.

Features

EPS foam has many features such as:

- Closed cell lightweight cellular plastics foam produced from polystyrene

- Material has been modified by the addition of flame retardant additives

- Gains excellent insulating properties from the stabilised air trapped within its cellular structure

- Contains no CFCs or any other gas that can escape to harm the ozone layer or decrease its insulation properties

- Highly resistant to the negative effects of moisture content

- Exceptional flotation properties

- Can withstand the effects of changes in temperature, thereby providing longevity in low temperature applications

- Impervious to vermin or pests, including termites

- Cost effective when compared to other insulating foams

- Polystyrene can be painted with non-solvent based paints

Applications

The main applications for products manufactured from EPS foam are:

- Thermal insulation systems (wall, roof and sub-floor)

- Ceiling panels and other decorative surfaces

- Concrete voids and block outs

- Pipe insulation

- Protective packaging

- Flotation and buoyancy applications

- Stage sets

You can read more about expanded polystyrene EPS foam in these reports published by the Plastics Association of Australia: